E6S-088 A Motion to Optimize, Smart Time-wise - Time and Motion Studies - Part 1

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, brought to you by E6S Industries, your source for expert training, consulting, and leadership in business performance and continuous improvement methods, like Lean and Six Sigma. In this episode number 88, "A Motion to Optimize, Smart Time-wise -Part 1" we introduce time and motions studies. Here we go. http://bit.ly/E6S-088; http://bit.ly/E6S-iTunes

****A Motion to Optimize, Smart Time-wise - Time and Motion Studies****

Objection 1: I thought you said Time Studies weren't necessary for a Value Stream Map. Why is it important now?

Counter 1: A VSM can bring you very far, perhaps 95% of the way. When you’re fully loaded and having capacity issues, that extra 5% can still make a big difference. Now that work much of the NVA in the value stream is removed on the more macro level, it’s time to look at the more Value-Added steps in greater detail, still looking for NVA work, but on the granular level.

Objection 2: This is too much detail, and I work in a high-mix low volume area. This won't work for me.

Counter 2: It is true that these methods are easiest to apply in a low mix, high volume production, where work tasks are repetitive. Time and motion studies alone won’t optimize the high mix cell, but still play a critical role to be more flexible with planning and resources. Without these optimizations, high mix work cells become chaotic.

I What is it?

a. business efficiency technique

i. Time Study work of Frederick Winslow Taylor

ii. Motion Study work of Frank and Lillian Gilbreth.

b. Direct observation of a task, noting time, inefficiencies, problems,

i. Each task time recorded

ii. Motion documented and illustrated

1. May be augmented with video – very easy these days

II Why do it?

a. When you cannot balance your workload enough to meet your takt time

b. When you’ve met your takt time, but want to decrease it

i. Reduce resourcing

ii. Reduce production hours on thatproduct

III How to do a time and motion study

a. GM You-tube video,

i. https://www.youtube.com/watch?v=k9vIhPszb2I

b. Some tools

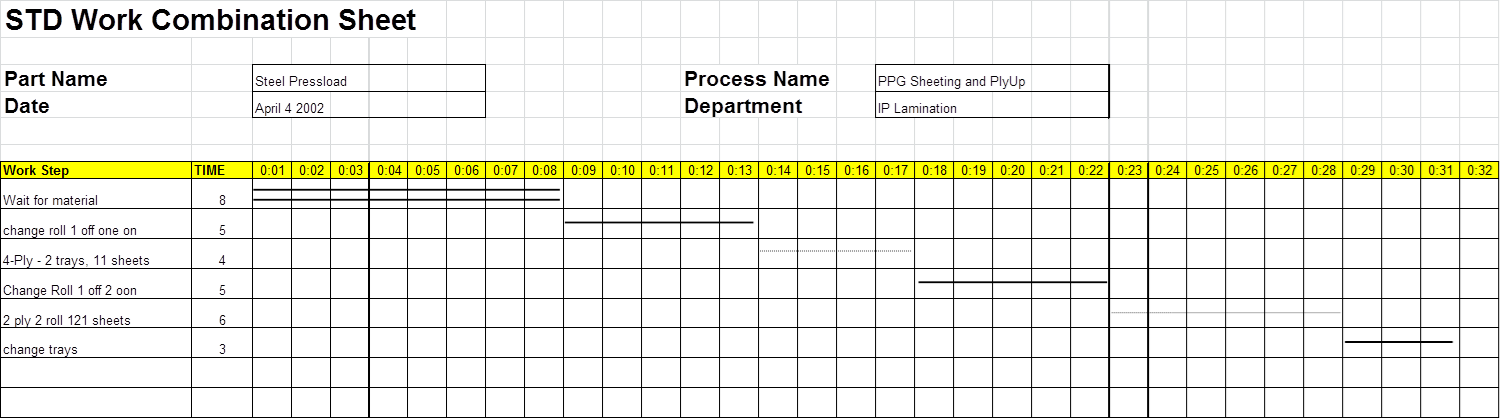

i. Standard Work Combination Sheet (SWCS). Document times with different symbology

1. Machine Time (Automatic) time

a. Machine is doing the Value-added work or fully automated, without the need for an operator

b. Operator can do another task in parallel

2. Manual Time

a. Manual work without the use of the VA machine (other tooling may be used)

b. May be a preparation step

c. May be a rife with excess motion

3. Manual Machine Time

a. Requires both Manual work and machine time

b. Could be manual machining

c. Could be automated but operator cannot walk away

i. Some localized prep work for another job may be possible

1. Logging in parts

2. Quality checks

3. Other machine maintenance checks

ii. Time/Motion note sheet

Outro: Thanks for listening to episode 88 of the E6S-Methods Podcast. Stay tuned for episode 89 where we continue with our discussion on time and motion studies. If you would like to be a guest on the podcast, contact us through our website. Join our mailing list! Subscribe to past and future episodes on iTunes or stream us live on-demand with Stitcher Radio. Don't forget to leave a review and share us with a friend. Get your free access to episode outlines and graphics or purchase full episode transcripts at www.E6S-Methods.com. “Journey Through Success”