E6S-089 A Motion to Optimize, Smart Time-wise - Time and Motion Studies - Part 2

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, brought to you by E6S Industries, your source for expert training, consulting, and leadership in business performance and continuous improvement methods, like Lean and Six Sigma. In this episode number 89, "A Motion to Optimize, Smart Time-wise -Part 2" we introduce time and motions studies. Here we go. http://bit.ly/E6S-089; http://bit.ly/E6S-iTunes

Objection 1: I thought you said Time Studies weren't necessary for a Value Stream Map. Why is it important now?

Counter 1: A VSM can bring you very far, perhaps 95% of the way. When you’re fully loaded and having capacity issues, that extra 5% can still make a big difference. Now that work much of the NVA in the value stream is removed on the more macro level, it’s time to look at the more Value-Added steps in greater detail, still looking for NVA work, but on the granular level.

Objection 2: This is too much detail, and I work in a high-mix low volume area. This won't work for me.

Counter 2: It is true that these methods are easiest to apply in a low mix, high volume production, where work tasks are repetitive. Time and motion studies alone won’t optimize the high mix cell, but still play a critical role to be more flexible with planning and resources. Without these optimizations, high mix work cells become chaotic.

III How to do a time and motion study

a. GM You-tube video,

i. https://www.youtube.com/watch?v=k9vIhPszb2I

b. Some tools

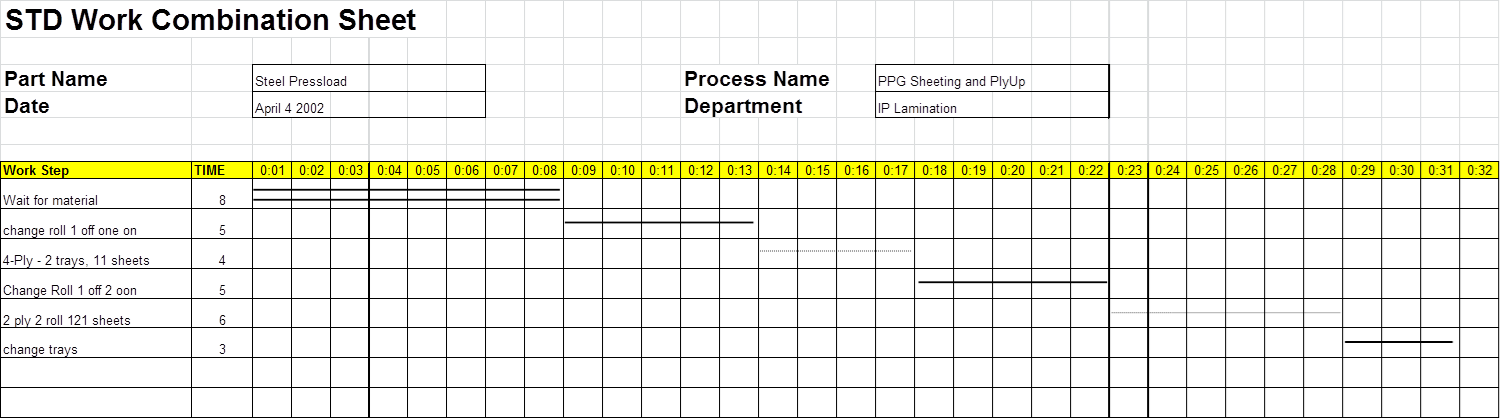

i. Standard Work Combination Sheet (SWCS). Document times with different symbology

1. Machine Time (Automatic) time

a. Machine is doing the Value-added work or fully automated, without the need for an operator

b. Operator can do another task in parallel

2. Manual Time

a. Manual work without the use of the VA machine (other tooling may be used)

b. May be a preparation step

c. May be a rife with excess motion

3. Manual Machine Time

a. Requires both Manual work and machine time

b. Could be manual machining

c. Could be automated but operator cannot walk away

i. Some localized prep work for another job may be possible

1. Logging in parts

2. Quality checks

3. Other machine maintenance checks

ii. Time/Motion note sheet

c. Go to Gemba

i. Do it!

1. Watch the work

2. Document the motion taking place

a. Draw it out “Spaghetti”

b. Film it

c. Measure it

d. Etc

3. Have a partner time it

4. Do this multiple times for accuracy

5. Brainstorm potential improvements

a. Rely on the line operators for ideas

b. Make them part of identifying the issues and experiments for improvement

6. Rinse & Repeat

ii. Ingot Grinding example: Motion

iii. Ingot Grinding Example : Time

IV Illustration of excess Motion,

[Frank Gilbreth and his wife, Lillian, employed time-lapse photography to verify their study and philosophy of “work simplification,” the relationship of human effort to the volume of work that the effort accomplishes. This photograph was used by the Gilbreths to study micromotion, which they achieved by attaching a camera to a timing device.: Motion Efficiency, Frank Gilbreth Motion Study 8, Photography Techniques, Paintings Photo, Lighting Paintings, Trav'Lin Lighting, Lillian Gilbreth, Art Shit, Efficiency Study]

V How wastes fit in; Revisit MR TOYOTA

a. Motion

b. Reserves

c. Transport

d. Overproduction

e. Yield Issues

f. Over-processing

g. Talents

h. Awaiting Availability

VI Criticisms

a. Taylor’s time study work was considered motivated by his belief that workers were lazy. Workers may regard a time study as a disguised tool of management designed to drive them to work harder, rather than allow them to be more efficient and effective.

b. When time is used as the Business Unit Currency. Time studies were used to develop a standard cost model for a product, rather than drive improvements

i. Standard times are inflated, (the more time “delivered” per part, the better)

ii. When in a pinch to meet month-end of man-hours delivered - high volume, high time currency, but easy parts took priority over parts that were due sooner.

****A Motion to Optimize, Smart Time-wise - Time and Motion Studies****

Outro: Thanks for listening to episode 89 of the E6S-Methods Podcast. If you would like to be a guest on the podcast, contact us through our website. Join our mailing list! Subscribe to past and future episodes on iTunes or stream us live on-demand with Stitcher Radio. Please leave a review while your there. Don't forget, theSomerville Lean Six Sigma and Project Management Meetup group is going active in New Jersey on September 8th. Be sure to RSVP. http://bit.ly/1IpdknB And I'll be in Atlanta, GA for the Institute for Industrial Engineers 2015 Engineering and Lean Six Sigma Conference Sept 30 to Oct 2nd. Let's meet up there too! http://www.iienet2.org/leansixsigma/ Find outlines and graphics for all shows and more at www.E6S-Methods.com. “Journey Through Success”