E6S-068 In the eye of the Cash-holder -Part 3B-Capability Indices

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your source for expert training, coaching, consulting, and leadership in Lean, Six Sigma, and continuous improvement methods. In this episode number 68, we finish up with the capability jargon with part 3B in this “In the Eye of the Cash-holder” series. Here we go. http://bit.ly/E6S-068

Objection 1: In spec is good enough. Variation doesn't matter.

Counter 1: Any variation from target results in depleted function of your customer. Although customer specs are wide, customers often have to account for supplier variation in some other way, and end up releasing lower quality goods into the market. Variation is evil according to Taguchi, not just to customers, but to society as a whole.

Objection 2: Cpk and other fancy jargon is on its way out.

Counter 2: Perhaps, but new jargon will surely take its place to describe process variation relative to outcome expectations

Part 3B

Process Capability Indices (cont.)

I Sigma Level/ Z Bench/ Z-score

a. Z-score = Number of Standard Deviations a value is from the Mean

i. For capability, how far is the USL or LSL away from the mean in units of “sigma?”

1. “Six Sigma”, Z-scores for the USL and LSL are at least 6 sigma (short-term) away from the mean

b. To calculate the overall Benchmark Sigma for the process (Zbench),

i. Add the percentages calculated to be outside the USL and LSL.

ii. Determine the z-score from cross reference of conversion tables or software

(caveate: Beware the 1.5 Sigma Shift, i.e a DPMO of 3.4 actually corresponds to z = 4.5, not 6. More on this in a later episode)

1. Mintab’s “Inverse Cumulative Probability Distribution” Function

2. Excel’s “NORMSINV” function

3. Sigma Conversion Table below

II DPPM / % Defective

a. Calculated by Rolled Throughput Yield : RTY = e^-(DPU) = IPY1*IPY2*IPY3*....IPYn (recall episode 12, “Yield to Defects – Project Metrics; Measure the Right Stuff Part 2.”

b. Or reverse calculated from Z-score (+/- 1.5 sigma depending on whether it is short-term or long-term.

i. Mintab’s “Cumulative Probability Distribution” Function

ii. Excel’s “NORMSDIST” function

iii. Sigma Conversion table above

c. Or Capability Studies function in Minitab to find everything

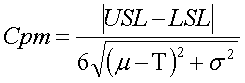

III CPM The Taguchi Index (Cpm):

a. Places more importance on the target value (T).

b. Places less importance on the specification limits.

c. Expresses variation from the target as 2 components: Process variability (σ) and process centering (μ – T).

d.

i. Cpm= 1 when it is a perfectly centered 3 Sigma process, and the mean is centered on Target

ii. The greater the variation and the further the Mean is from Target, the lower the Cpm.

iii. Cpm is equal to Ppk when the Target and the Mean are identical.

Outro: Thanks for listening to episode 68 of the E6S-Methods Podcast. Stay tuned for episode number 69, “Good Intentions, Artifacts, and Truncated Lies,” capability studies gone wrong. If you would like to be a guest on podcast, contact us through our website or tweet us @e6sindustries. Join our discussions on LinkedIn. Subscribe to past and future episodes on iTunes or stream us live on-demand with Stitcher Radio. Leave a 5-star review while you’re there. Find outlines and graphics for all shows and more at www.E6S-Methods.com. “Journey Through Success”