E6S-123 FMEA 10*10*10 Explodes Repeatedly Without Warning - Part 2

Like / Dislike **We'd Appreciate Your Opinion**

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your weekly dose of tips and tricks to achieve excellent performance in your business and career. Join us as we explore deeper into the practical worlds of Lean, Six Sigma, Project Management and Design Thinking. In this episode number 123, Jacob and I continue our introduction to the FMEA. If you like this episode, be sure to click the "like" link in the show notes. It's easy. Just tap our logo in the artwork, click and you're done. Tap-click-done! Here we go. http://bit.ly/E6S-123 Leave a Review! http://bit.ly/E6S-iTunes

***FMEA 10-10-10 - Explodes Repeatedly Without Warning***

I Design FMEA

a. Functional FMEA:

i. high level functions can be evaluated on potential functional failure effects.

ii. Proactively design-out or mitigate the failure.

b. Concept Design / Hardware FMEA:

i. Analysis of a concept or prototype system or subsystems for failure mechanisms and lower level functional failures

ii. May be used to compare different concepts and trade-off analysis

c. Detailed Design / Hardware FMEA:

i. Detailed analysis of products (final concepts) prior to production.

ii. based on components or hardware breakdown (e.g. the BoM = Bill of Material)

II Process FMEA: Analyze processes for functional breakdowns. Affects quality and reliability (manufacturing, assembly, transport, business processes, services)

a. Personal preferences

i. Jacob's approach

1. Process map àFishboneà C&E matrix àFMEA (if necessary)

ii. Aaron’s approach

1. Detailed Process Map à FMEA

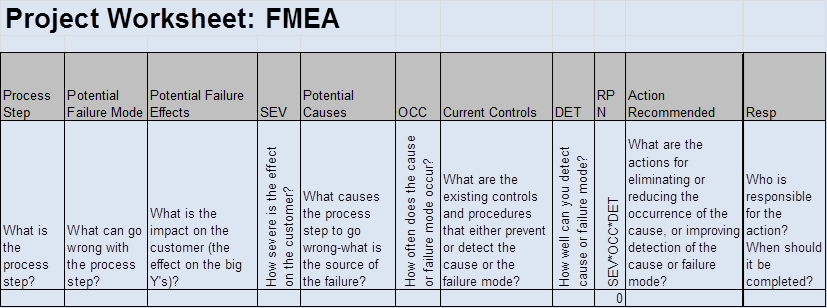

b. PFMEA Procedure

i. List process steps individually

1. For design, could be features, assemblies or individual components

ii. Brainstorm the potential failure modes and effects of those failures for each step (may be multiple)

iii. Score the Severity of the effects –

1. High Severity (10) linked to safety issues, down to low severity (1), more of a “nuisant” loss or minor inconvenience

iv. Identify potential root causes (mechanisms) for the failure mode

v. Score the Occurrence based on the probability of the root cause (if known) or the failure mode

1. High Occurrence (10) means extreme probability of occurring. Linked to process capability (yield or failure data), or similar designs. Low Occurrence (1). Never happened and highly unlikely to happen (black swan?)

vi. Identify the controls in-place to detect or prevent the failure effects

vii. Score the Detection based on the quality of the control system to detect or prevent the problem

1. Low Detection (10) indicates the error is likely to not be captured before the outcome severity is realized.

viii. Multiplied together – Risk Priority Number (RPN = SEV*OCC*DET)

1. (10*10*10) Explodes Repeatedly Without Warning - Highest possible risk (RPN = 1000)

a. Extreme Severity – 10 (serious injury or death)

b. High Occurrence – 10 (commonplace, everyday)

c. Low Detectability – 10 (by surprise, without warning)

ix. Identify action items, each high scoring RPN - Priority on safety risks

1. Further study

2. Design of Experiments

3. Mistake Proofing

4. Re-engineering

x. Rescore Severity, Occurrence, and Detection after counter-measures are implemented

xi. Continually update and maintain living record to capture new failures and countermeasures

III Pitfalls

a. The Incredible exploding FMEA “Explodes Repeatedly Without Warning”

i. One process step starts with one line, explodes to 12 lines

1. 3 failure modes

2. 2 effects (each failure mode)

3. 2 root causes (each effect)

4. 1 control per failure mode

Outro: Thanks for listening to episode 123 of the E6S-Methods podcast. Don't forget to click "like" or "dislike" for this episode in the show notes. Tap-click-done! We love hearing from our listeners and learning about how you use Lean and Six Sigma. Feel free to email us, aaron@e6s-methods.com, or contact us through our website, we reply to all messages. Reviews on iTunes are always appreciated and keeps us higher in the ranks and allows us to reach more superstars like you. Don't forget to you can find notes and graphics for all shows and more at www.E6S-Methods.com. "Journey Through Success. If you're not climbing up, you're falling down? Leave a Review! http://bit.ly/E6S-iTunes