E6S-050 Rule out the Ruler Part 2 - Measurement Systems

Intro: Welcome to the E6S-Methods podcast with Jacob and Aaron, your source for expert training, coaching, consulting, and leadership in Lean, Six Sigma, and continuous improvement methods. In this episode number 50 “Rule out the Ruler” Part 2, we continue our review of measurement system fundamentals, discussing repeatability, reproducibility, and the importance of calibration, both inside and outside of the lab. Here we go.

II Accuracy vs. Precision

a. Accuracy – Measurement comparison to actual known standard value

i. Bias – reading offset from a known value.

“I know my home scale shows a bias, because when I step on it, it says I weigh 5 pounds more than I actually do.”

ii. Linearity – A change in bias over the scale’s measurement range.

“I know my home scale shows linearity, because when my wife steps on it, it says she’s 10 pounds more than she actually is, (vs. only a 5 pound difference for me).”

iii. Stability – changes is bias over time.

1. Example: Standard everyday measurements, varying either randomly or trending.

2. Stability issues may indicate uncontrolled external factors (like temperature, expiration, or wearing components.)

b. Precision – Ability to consistently measure the same value

i. Repeatable – variation within a single user/operator

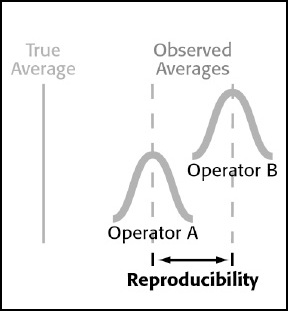

ii. Reproducible – variation between users/operators

c. Calibration – Process employed to check and correct for inaccurate gauges, most commonly referring to physical measurement devices lacking stability. Definition can be expanded to correct for deficiencies in an entire measurement system. (This could turn out to be your project).

i. Mechanical tuning –

1. Correct for drift over time, (stability)

2. Replace wear components

ii. Retraining – Brings user back to the proper methods. Addresses drift (instability) from best practices.

iii. Clarification and Standardization of Methods & Materials – Clears up variation in interpretation between different users, and variation due to tooling & consumables.

III Resolution – Ability to subdivide the measurement system (continuous) into smaller bits. (Fractions, decimal points). Smallest distinguishable size, smallest discrete level. (0.1 grams vs 0.001 grams, 1/8 inch vs. 1/32 inch .

a. The “higher” the resolution, the “smaller” the discrete distinguishable measurement size possible.

i. Measured in “buckets”, higher resolution than barrels. Tablespoons higher resolution than cups.

b. Often believed a function of equipment, but really is a function of the entire measurements system & inputs to it.

Outro: Thanks for listening to episode 50 of the E6S-Methods Podcast. Stay tuned for episode number 51, “Beware the Lean Six Sigma Holiday Blues,” how the holidays can wreak havoc on your project, and what actions you can take to prevent total derailment. Subscribe to past and future episodes on iTunes or stream us live on-demand with Stitcher Radio. Have an idea for an episode? Contact us! Follow us on twitter @e6sindustries. Join a discussion on LinkedIn. Find outlines and graphics for all shows and more at www.E6S-Methods.com. “Journey Through Success”