E6S-011 Project Metrics- Part 1- Measure the right stuff

Why do you need Metrics?

Metrics are used to drive improvements and help businesses and project leaders focus their people and resources on what’s important.

In many organizations, the improvements made from projects need to be quantified for savings and having good metrics is key to be doing a thorough benefit analysis at the end of the project

Metrics help point the team on:

· Where the process/project has been

· Where the process/project is heading

· Whether something is going wrong

· When the project has reached its goal

Good metrics will:

· Drive the strategy and direction of the organization

· Provide focus for the organization, department or employee

· Help make decisions

· Drive performance

I How to choose a solid metric & avoid bad ones

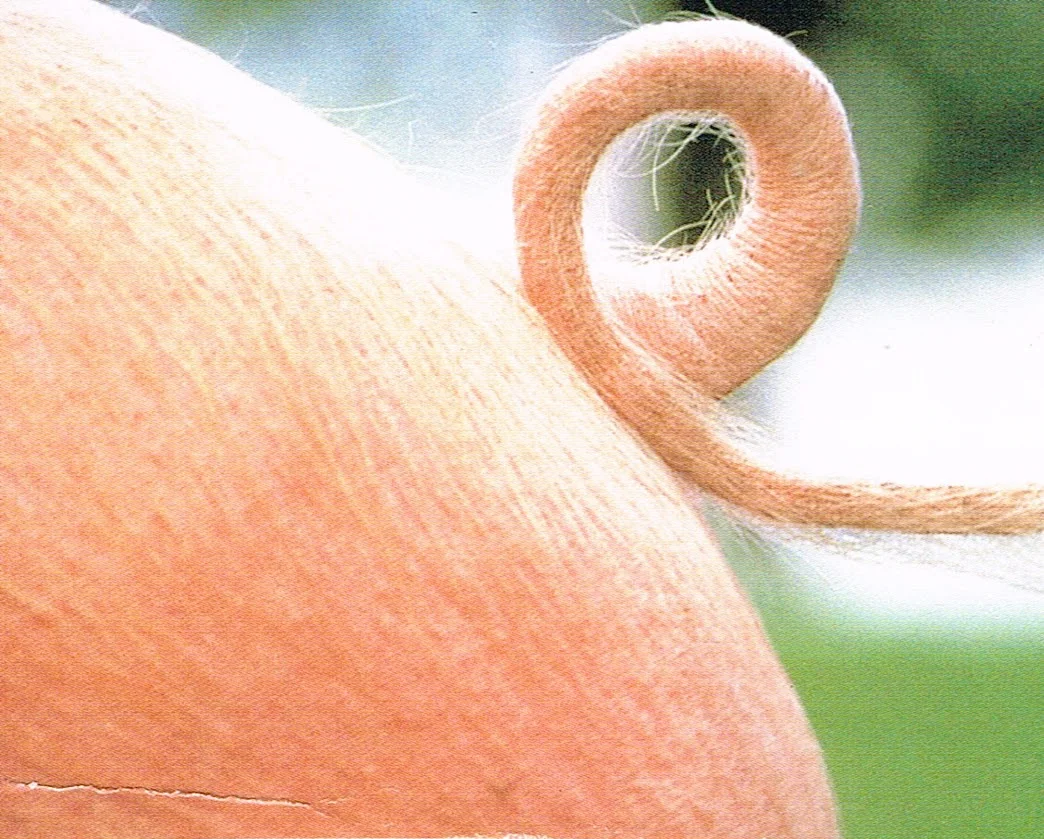

a. Examples of how to cheat a metric (pig tails, OTD, $ per line item, product yields)

i. Pig Tails (Reference Freakonomics podcast “The Cobra Effect” http://freakonomics.com/2012/10/11/the-cobra-effect-full-transcript/). : Overpopulation of pigs, Fort Benning. Goal was to decrease wild pig population. What resulted was an over abundance of pigs. Metric was a measure of pig tails turned in (hunted and killed). People paid $40 on a per tail basis. Was easier to raise and slaughter your own pigs for their tails than to hunt them down. Large farms were created just to harvest tails for money. When these farms were shut down, farmers released the pigs into the wild.... and now a bigger pig problem.

1. Pitfalls: ignoring the human “cheating/gaming” or “lazy” or “innovative” nature; over-confidence in the “pig-tail” metric tie to the end goal (business metric improvement), not paying close enough attention to the consequential metrics

ii. OTD example: Wish to improve On-time-delivery There are many ways to achieve this goal, some would be a detriment to the business. (First discuss why OTD is something to be improved OTD--> Cust Satisfaction & faster payment --> Greater credility & loyalty, organic growth--> brand enhancement and new business:

1. Change the customer lead-time terms to account for internal company constraints.

2. Re-negotiate delivery promise dates when it’s clear they will be missed.

3. Reduce capacity constraints and remove waste and time traps to improve throughput time in the value stream.

4. Put a cap on orders to only work on what can be delivered on-time... or only do the easier products.

5. Add overtime or another shift to handle capacity

6. Stock inventory to pull off the shelf in-time.

Each appears to achieve the singular goal of improving OTD, but only addressing the capacity constraints and time traps does so without having a negative impact on the customers or the business.

II There are several types of metrics that should be measured during a project (primary, secondary, consequential, financial and business)

a. Make an example (product yields?) including secondary and consequential metrics.

i. Primary: Reduce % Scrap in assembly department.

ii. Secondary (a good side effect): Improved On-time delivery due to product availability.

iii. Consequential Metric Type 1 (negative effect due to mismanaged metric, not project success. Achieves primary metric at the expense of the business):

1. Reduce % scrap by inserting a rework step before quality inspection.

2. Reduce % scrap by slowing down the process by 50%.

3. Reduce % scrap by increasing headcount in area.

4. Changing production mix to easier parts (that the customer didn’t order).

Ref( Thomas Pyzdek “Denominator Improvement” Gaming the metric. http://www.sixsigmatraining.org/introduction-to-six-sigma/gaming-the-metrics.html.

iv. Consequential Metric Type 2 (negative side effect due to project success ... i.e. chain reaction): Increase in finished goods inventory, due to increased output.

v. Financial Benefits: Financial estimates of “soft” benefits and P&L proof of “hard” benefits.

1. Ref: Good Article in iSixSigma by Michael Ohler February 26, 2010 http://www.isixsigma.com/methodology/metrics/be-consistent-six-sigma-project-metric-selection/