E6S-082 The Truth to Executives: You Can't Handle the Truth...

Intro: For this episode number 82 we will feature a blog-post and excerpt from an upcoming book called, "Is Lean Six Sigma Right for Me?" One of two books coming out soon from E6S Industries. It's a short episode, and something different. Here we go. http://bit.ly/E6S-082; http://bit.ly/E6S-iTunes

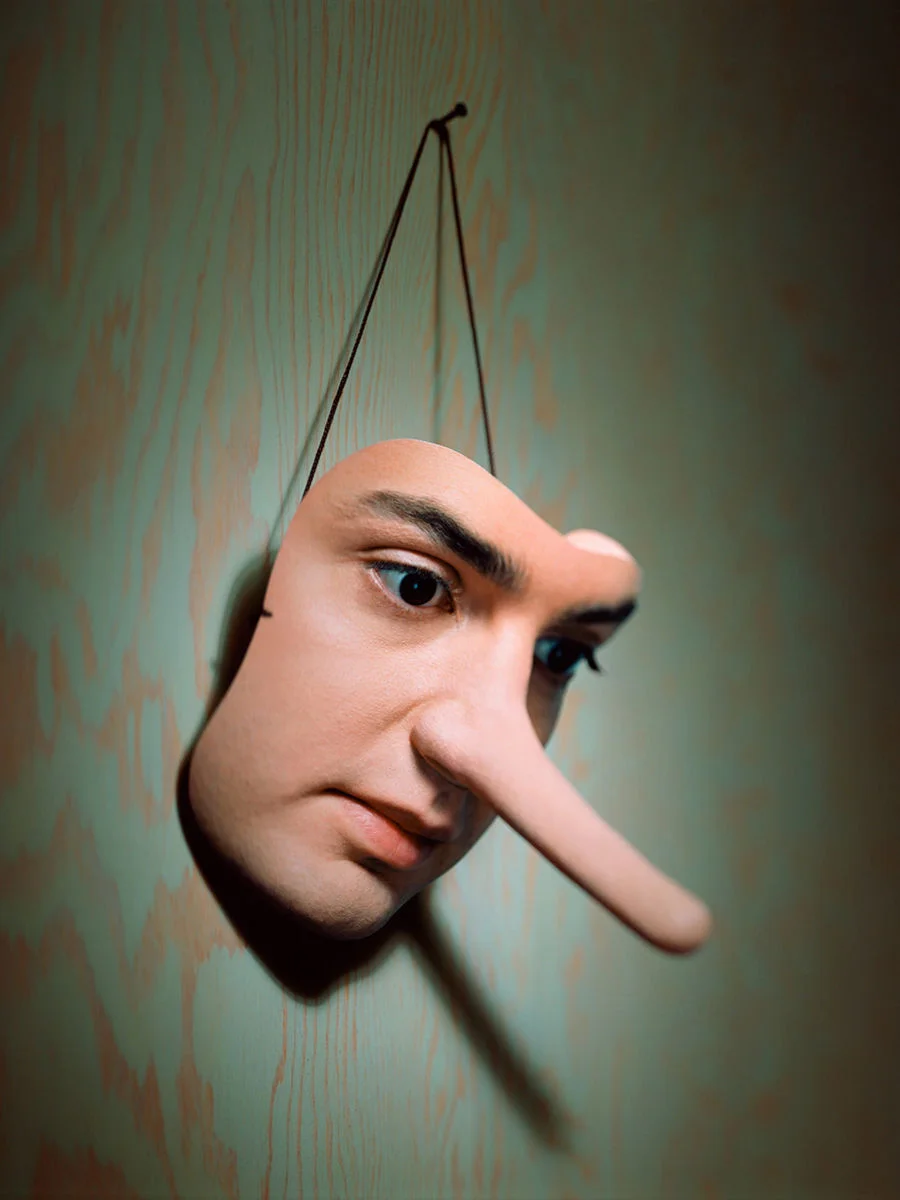

Can you handle learning they've all been lying to you this whole time?

Excerpt from Is Lean Six Sigma Right for Me?: a 'gut check' transformation guide for senior business leaders - By Aaron A. Spearin, MBB, PMP ; E6S Industries, LLC

www.e6s-methods.com/book-releases

Executives! Newsflash! The metrics you bet your company on and measure your risks against are full of lies mixed with partial truths. The further you are from the front line, the greater the lies infiltrate the quarterly numbers you consume, those upon which you base your forward-looking decisions. Does this come as a surprise? It shouldn't. Before you got to where you are how honest were your numbers? Surely, they were framed in the utmost positive light possible. How different are monthly roll-up metrics from your own resume accomplishments? The best-in-class resumes are full of the same types of metrics that are used to run businesses, the same overly-simplified metrics that take a fourth-grade education to understand and game to one's own advantage (1) - rounding here, drop a decimal there, take a penny, leave a penny, etc.... Some of these lies are so white they are nearly translucent, completely lost in the noise of uncertainty, which, by the way, is also completely ignored in your metrics.

Even the whitest lies compound to bad decisions when they finally reach the top. It starts with confirmation or selection bias. Those counts of defects or events that are anti-bonus or pro "looks-bad," are rationalized out of the metrics, sometimes sub-consciously due to legitimate errors, but very often done consciously. Each "looks-bad" event is somehow explained away as something special -- extenuating circumstances that never happened before and would never ever happen again. These events become discounted and unofficially disposed as doesn't count, wasn't my fault, or they didn't notice last time, forever relegated to Quality Assurance limbo without a name, cause or corrective action. It doesn't take long for documented "extenuating circumstances" to become a rather full bag of neglected system flaws. This is really only true, though, if the company is fairly diligent at documenting events. Quite frankly, most systems contain so much "hidden factory" that these events are already camouflaged by BAU (business as usual) rework. (2) In the name of "expedience," operations, where they can get away with it, often give themselves at least one mulligan (3) before they even count a defect. I personally witnessed a standard one-mulligan practice in the aerospace industry and an infinite (non-standard) mulligan loop in the chemical industry.

With the best of intentions, each hidden factory is sub-optimize to make the best of a "looks-bad" situation. In the aerospace industry, they wanted these parts to be reworked right away so they would not be left wasting in some scrap bin, but instead could be salvaged quickly enough to ship with the order. However, in doing so, the parts bypassed the quality system and were not counted as defective, which artificially inflated the quality yield metrics.

In the chemical industry, it was so easy to remix the non-conforming batches, and anything that wasn't disposed of was counted as good, (on average). For those more complicated processes, a first sample mulligan was already factored in-- translation: "We never get this right the first time, so we include an in-process sample so we can adjust it before submitting the final [official] sample." Some chemical batches sold for as much as $1000 per liter, which, to many, justified the endless dollars spent. In reality, the disposal of these chemicals costs less than $100, including the raw material purchase price. Yet they poured dollars by the thousands into the financial overhead bucket as they tried to salvage these batches. This bucket doesn't even count the full excess burden put on the rest of operations. These "looks-bad" events cause a ripple, creating delays, shortages and capacity issues, all of which again fall into the murky margins of uncertainty, blending with the average overhead of every other operation that splits this burden. At best, this waste is captured in over-time hours, but with no real trace to a reason other than BAU.

While many other "looks-bad" events may be difficult to completely erase, such as in a call center where each call is logged and monitored "for quality purposes," it's still easy to explain away certain events, miss-categorize reason codes, or soften the blow by changing how the events will roll-up into that single magic number or ratio of events, (e.g. % Defective, First Pass Yield, Employee Turnover Rate, Lost Time Injuries, Customer Churn, etc.) "How, is this possible?" you may ask. Can you imagine the possibility where a worker can become amputated at work and not impact the safety metric? I once knew a dedicated soul who "took one for the team." He lost his finger and returned to work the same day, heroically preserving the zero lost-time injury streak they maintained for several years before that. That dedication followed him all the way up to the day he quit, less than two years later. Perhaps he received the quiet accolades of his immediate supervisor, celebrating his heroism. But more than that, and much much worse, in his good intentions he and his accomplice, (the lost-time metric), supported a big lie and shielded the truth; there were serious safety hazards that no one was tending to. The bonuses were paid out for maintaining the metric for reasons that were technically legitimate, even in the court of law. Everyone wins, except of course, for the man with a missing finger, and the next unsuspecting operator who has no idea there is an amputation risk at his or her work station.

So there you sit in disbelief, not that you don't believe the story, but that you deny such things could happen in your organization. You work with and hired truly honest, trust-worthy, hard-working heads of family with deep ties to the community. Integrity is part of your core mission and success pillars. It is said that the road to hell is paved with good intentions.-- so also are the roads to bankruptcy, bail-outs, and bubble-bursting golden parachutes. To this day, the villains of the most recent economic collapse admit to just doing their jobs. They made the numbers do what they were supposed to do -- these overly-simplified fourth-grade mathematical formulas that capture less than half the truth, (by nature of averages).(4) Would the CEO of the collapsed Lehman Brothers bank dare venture into public if he thought he had behaved so disgracefully? The 99-percenters applauded the assailant who decked Richard Fuld while he was running in the corporate gym shortly after announcing bankruptcy (5) -- casting off 26,000 workers (6), and defrauding the country. But he was just doing his job, and now he was the legitimized victim, technically speaking.

No, your people are not cut from cloths terribly different than the leaders in the companies I referenced or the fallen companies in recent US history. These were all hard-working pillars of community, good God-fearing people with strong moral fiber and family values. They all worked and earned their ways to the top by making the metrics perform, and they have stellar resumes to prove it, same as you. But they are all liars, and, for the most part, they don't even know it.....

Can you handle learning they've all been lying to you this whole time?

- E6S-011 Project Metrics- Part 1- Measure the right stuff — E6S Industries; http://bit.ly/E6S-011

- E6S-012 Project Metrics Part 2 -Yield to Defects- Measure the right stuff — E6S Industries; http://bit.ly/E6S-012

- mulligan- noun. Golf. a shot not counted against the score, permitted in unofficial play to a player whose previous shot was poor. ; dictionary.reference.com

- E6S-047 Variations - Part 1 — E6S Industries; http://bit.ly/E6S-047

- http://www.telegraph.co.uk/finance/financialcrisis/3150319/Richard-Fuld-punched-in-face-in-Lehman-Brothers-gym.html

- http://www.cbsnews.com/news/the-case-against-lehman-brothers-23-04-2012/

Outro: Thanks for listening to episode 82 of the E6S-Methods Podcast. If you would like more information regarding the release of "Is Lean Six Sigma Right for Me?" be sure to check out the "Book Releases" tab on the homepage. Also, check out the show notes for links and references for this post. If you would like to be a guest on the podcast, contact us through our website. Join our mailing list! Subscribe to past and future episodes on iTunes or stream us live on-demand with Stitcher Radio. Find outlines and graphics for all shows and more at www.E6S-Methods.com. “Journey Through Success”